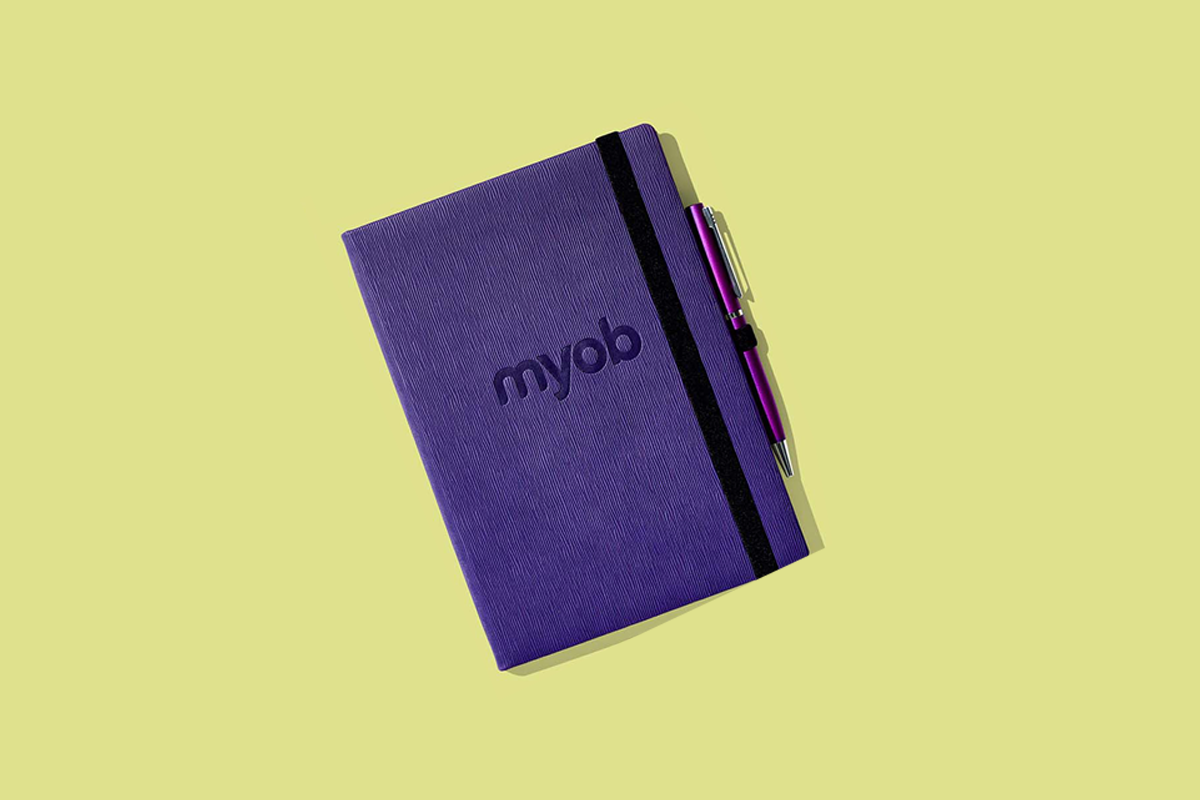

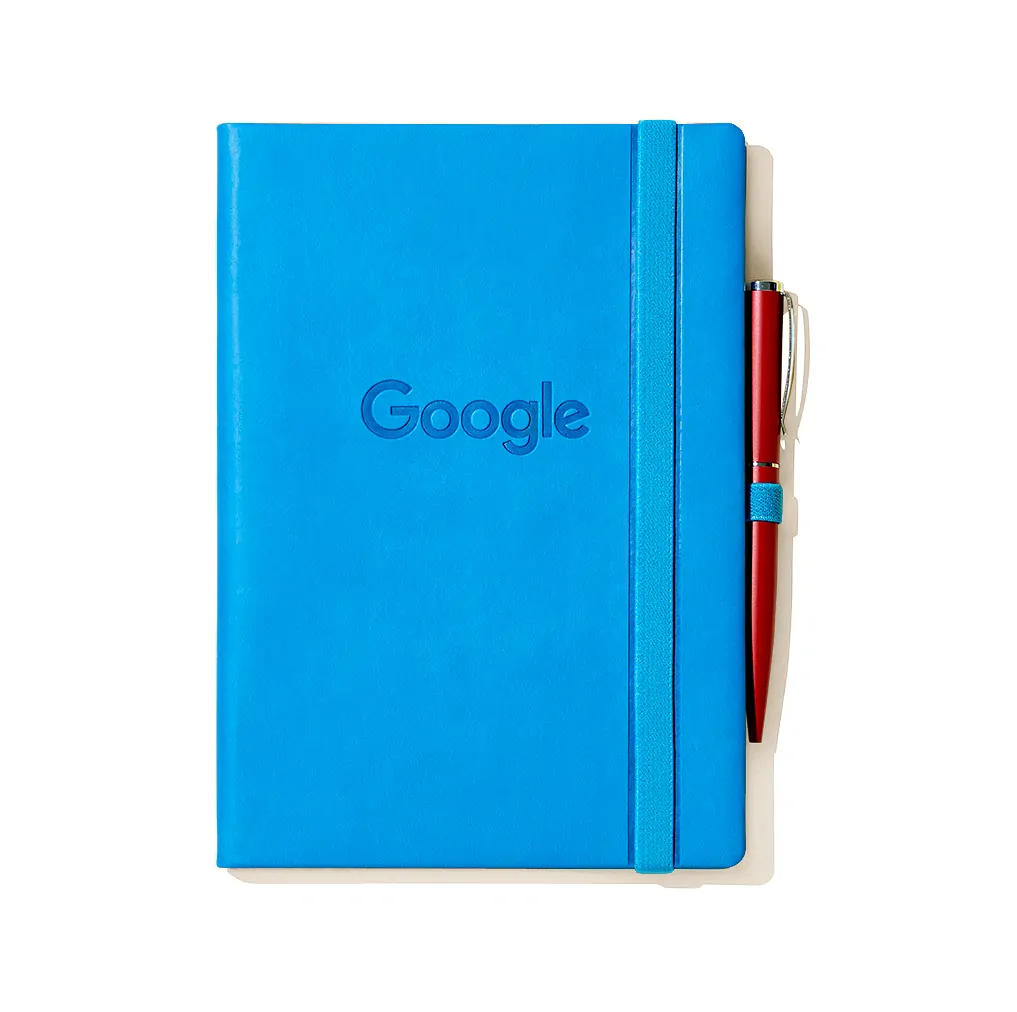

Description

Sumo lunch cooler with Venture Notebook, Napier Pen and Flat Drink Bottle.

Dimensions:

Cooler: 175 x 125 x 240mm (LxWxH)

Printable Area:

Screenprint: Lunch Bag – 110 x 100mm (LxH), Drink Bottle – 90 x 150mm (LxH), Notebook – 100 x 150mm (LxH); Digital Transfer: Lunch Cooler – 110 x 100mm (LxH); Digital Print: Drink Bottle – 90 x 150mm (LxH), Notebook – 100 x 150mm (LxH); Laser Engraved: Pen – 50 x 6mm (LxH); Pad Print: Pen – 50 x 7mm (LxH)

Additional information

| Production Time | 11 Working Days Production Time, 4 Working Days Production Time, 6 Working Days Production Time, 8 Working Days Production Time, 9 Working Days Production Time, 3 Working Days Production Time, 5 Working Days Production Time, 7 Working Days Production Time, 10 Working Days Production Time, 12 Working Days Production Time |

|---|---|

| Decoration | 1 Colour 1 Position Pad Print Pen, 1 Colour 1 Position Print Lunch Cooler, 1 Colour 1 Position Print Notebook, 1 Position Digital Print Drink Bottle, 1 Position Digital Print Notebook, 1 Position Digital Transfer Lunch Cooler, 1 Position Laser Engraved Pen, 1 Position Screenprint Drink Bottle, 2 Colour 1 Position Pad Print Pen, 3 Colour 1 Position Pad Print Pen, 4 Colour 1 Position Pad Print Pen, 4 Position Print (1 Laser + 2 Digital + 1 Digital Transfer) |

| Colour | Dark Blue, gunmetal, Light Blue, light green, Navy Blue, Silver, Teal, Orange, Red, Yellow, White, Black |

Our guarantee

All of our products are fully guaranteed to work, look and feel as designed.

Our most highly regarded company value at Good Things is integrity. We do what we say we are going to do in a timely fashion. We get "Back in a Flash" to all our clients for quotes, artwork and samples.

It is essential in our industry - from meeting delivery deadlines, through to having a product match a sample when delivered to each minute detail.

When dealing with us you can expect to get exactly what you ordered: as agreed, and on time. That is the Good Things Guarantee.

Product reviews

Office Pack

Min Qty: 50

99.4% jobs

delivered on-time

Free graphic

design

Quotes within

24 hours

Get an instant quote

Description

Sumo lunch cooler with Venture Notebook, Napier Pen and Flat Drink Bottle.

Dimensions:

Cooler: 175 x 125 x 240mm (LxWxH)

Printable Area:

Screenprint: Lunch Bag – 110 x 100mm (LxH), Drink Bottle – 90 x 150mm (LxH), Notebook – 100 x 150mm (LxH); Digital Transfer: Lunch Cooler – 110 x 100mm (LxH); Digital Print: Drink Bottle – 90 x 150mm (LxH), Notebook – 100 x 150mm (LxH); Laser Engraved: Pen – 50 x 6mm (LxH); Pad Print: Pen – 50 x 7mm (LxH)

Additional information

| Production Time | 11 Working Days Production Time, 4 Working Days Production Time, 6 Working Days Production Time, 8 Working Days Production Time, 9 Working Days Production Time, 3 Working Days Production Time, 5 Working Days Production Time, 7 Working Days Production Time, 10 Working Days Production Time, 12 Working Days Production Time |

|---|---|

| Decoration | 1 Colour 1 Position Pad Print Pen, 1 Colour 1 Position Print Lunch Cooler, 1 Colour 1 Position Print Notebook, 1 Position Digital Print Drink Bottle, 1 Position Digital Print Notebook, 1 Position Digital Transfer Lunch Cooler, 1 Position Laser Engraved Pen, 1 Position Screenprint Drink Bottle, 2 Colour 1 Position Pad Print Pen, 3 Colour 1 Position Pad Print Pen, 4 Colour 1 Position Pad Print Pen, 4 Position Print (1 Laser + 2 Digital + 1 Digital Transfer) |

| Colour | Dark Blue, gunmetal, Light Blue, light green, Navy Blue, Silver, Teal, Orange, Red, Yellow, White, Black |

Our guarantee

All of our products are fully guaranteed to work, look and feel as designed.

Our most highly regarded company value at Good Things is integrity. We do what we say we are going to do in a timely fashion. We get "Back in a Flash" to all our clients for quotes, artwork and samples.

It is essential in our industry - from meeting delivery deadlines, through to having a product match a sample when delivered to each minute detail.

When dealing with us you can expect to get exactly what you ordered: as agreed, and on time. That is the Good Things Guarantee.

Australian-Owned

Australian-Owned

The good range

The good range Bags

Bags Caps & Hats

Caps & Hats Clothing & Apparel

Clothing & Apparel Confectionery

Confectionery Conferences & Events

Conferences & Events Drink Bottles

Drink Bottles Eco Friendly

Eco Friendly Giveaways

Giveaways Keyrings

Keyrings Mugs

Mugs Outdoor

Outdoor Packaging

Packaging Pens & Stationery

Pens & Stationery Technology

Technology Umbrellas

Umbrellas

Free Shipping

Free Shipping