Description

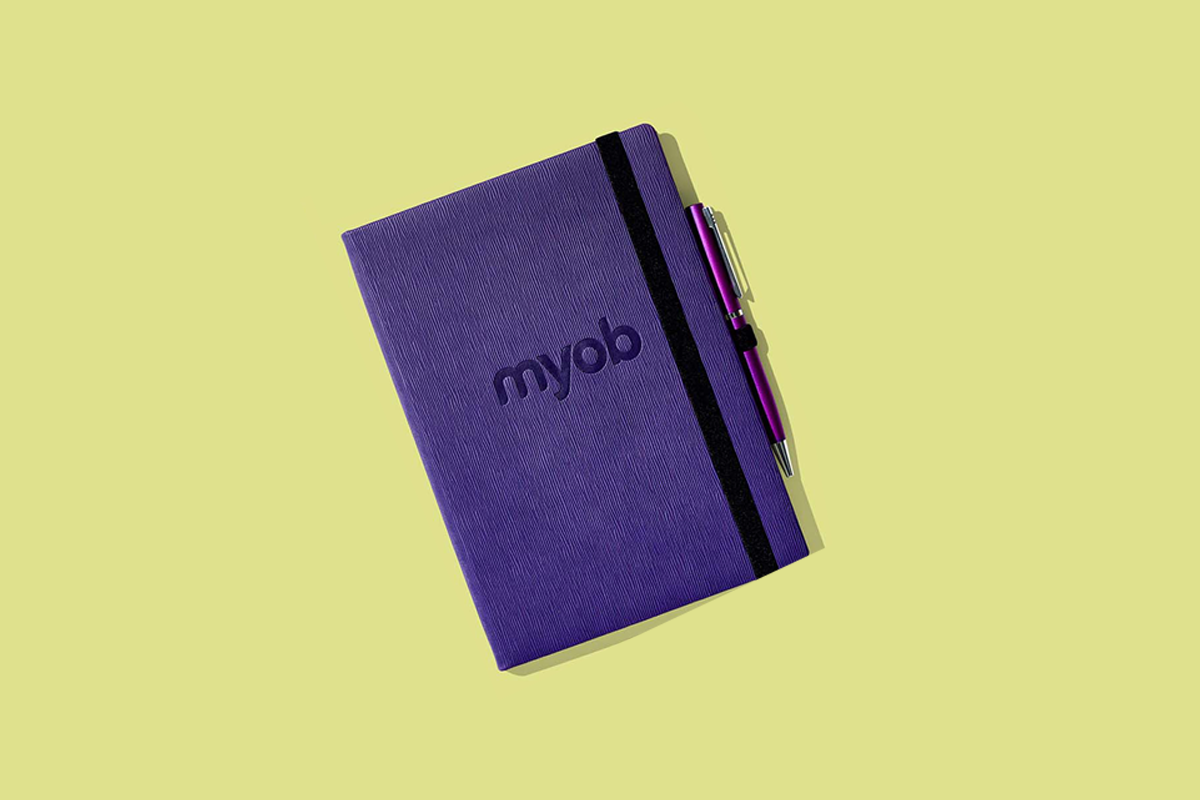

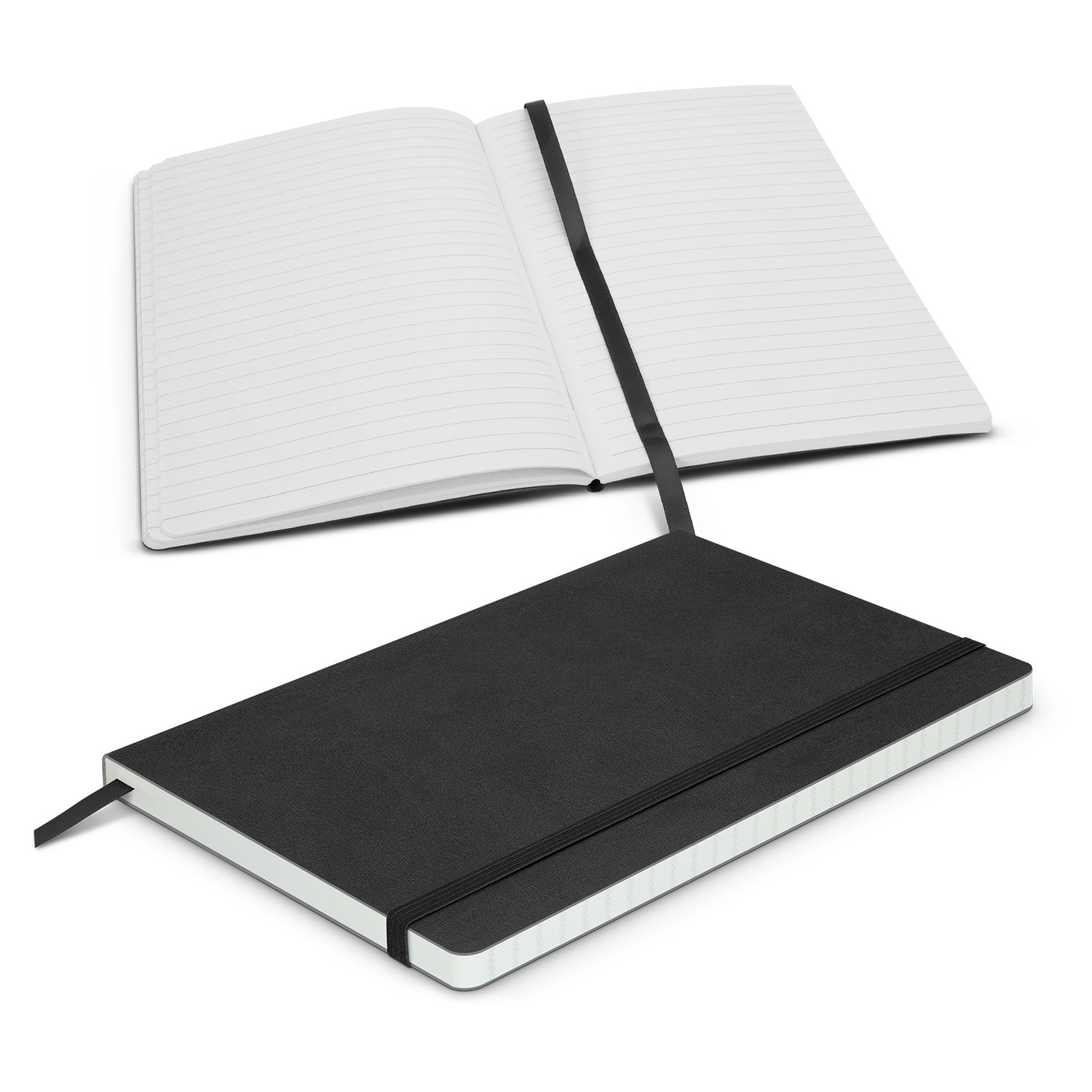

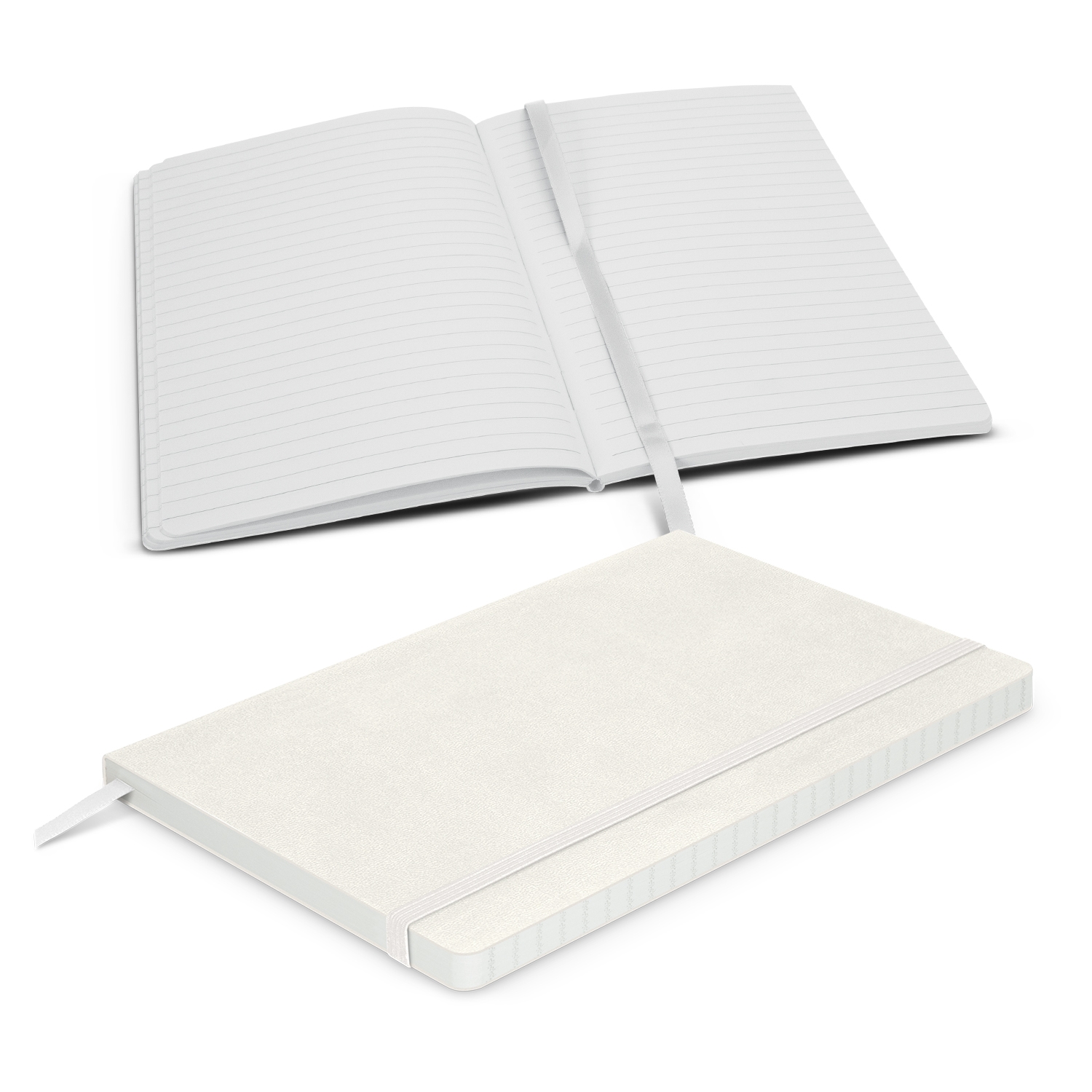

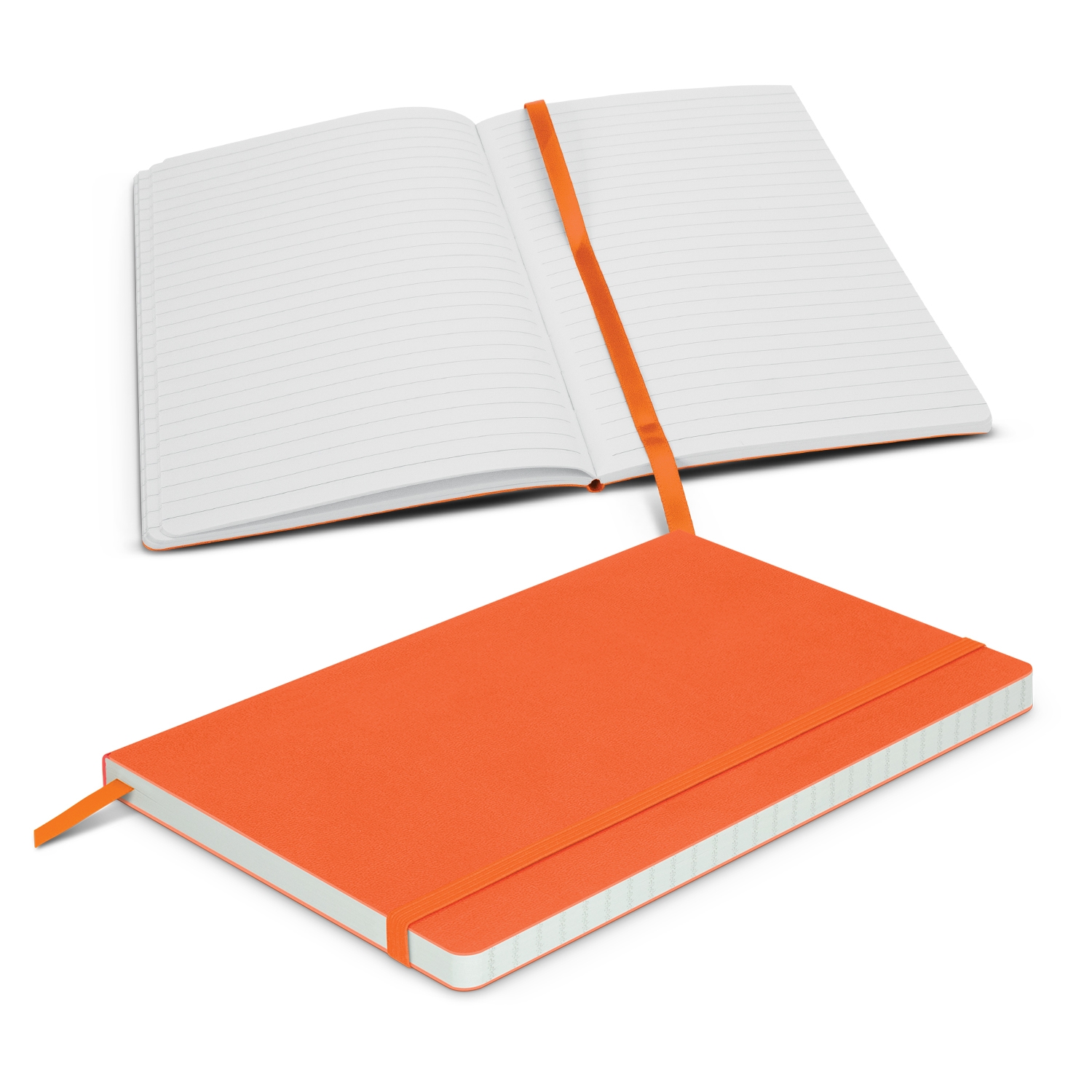

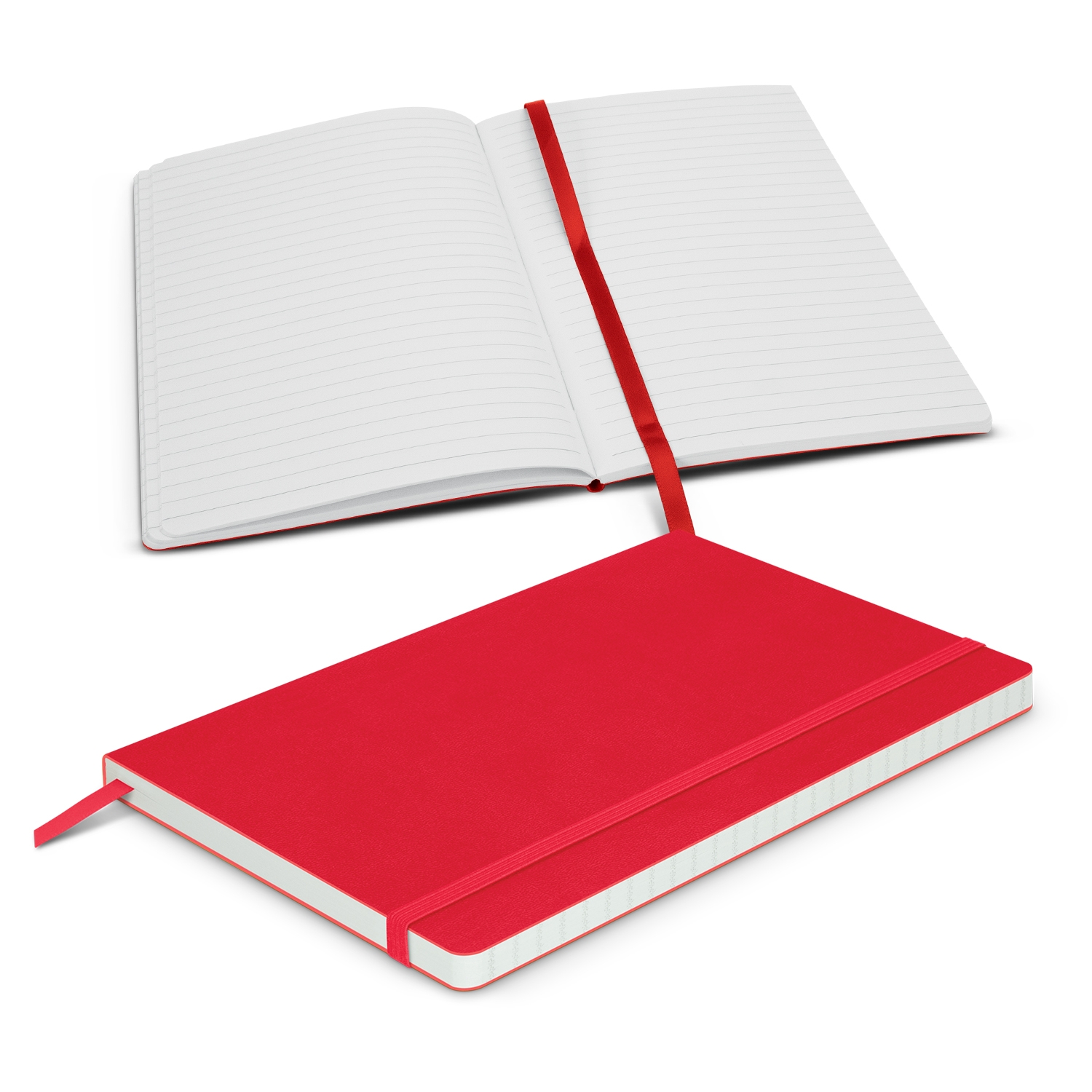

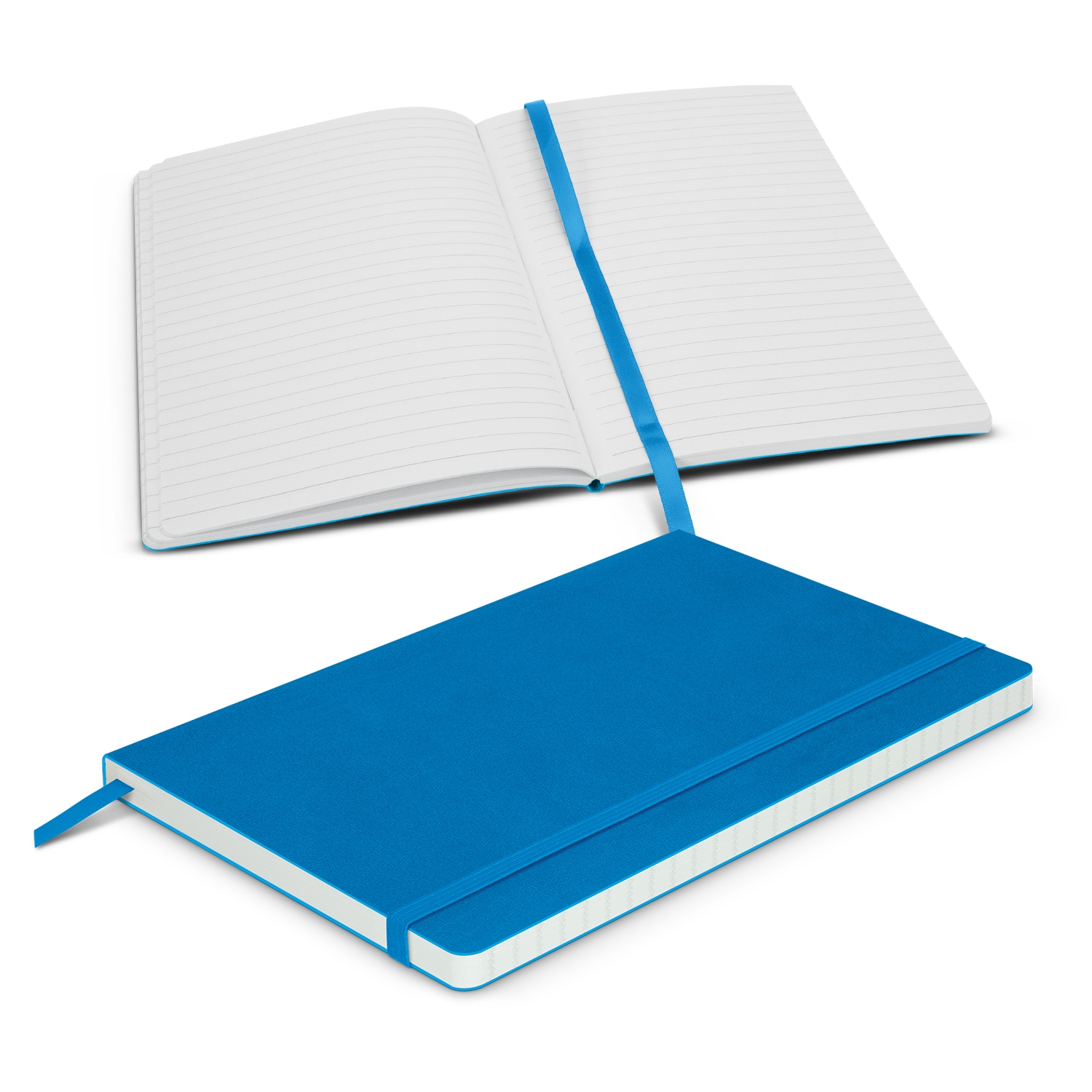

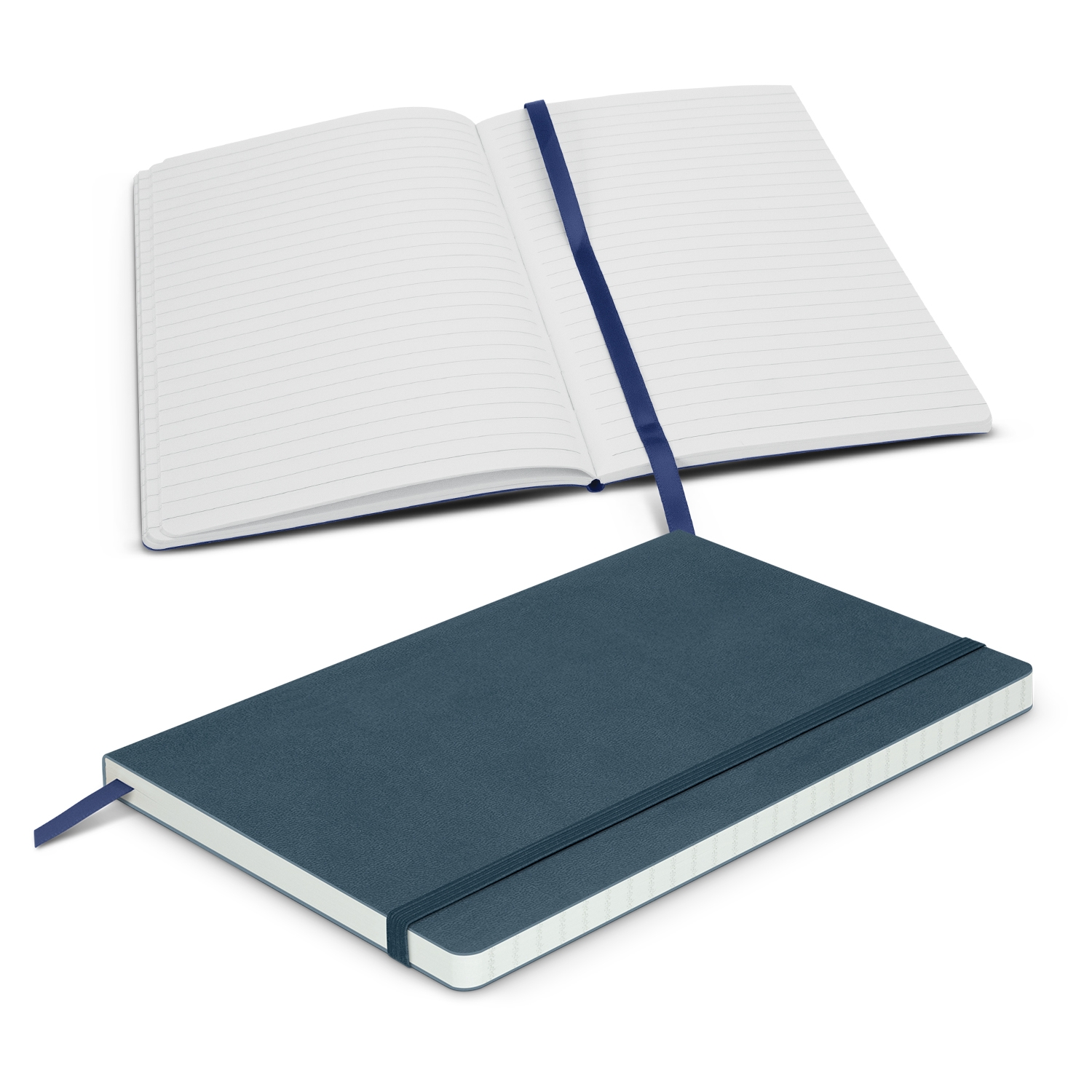

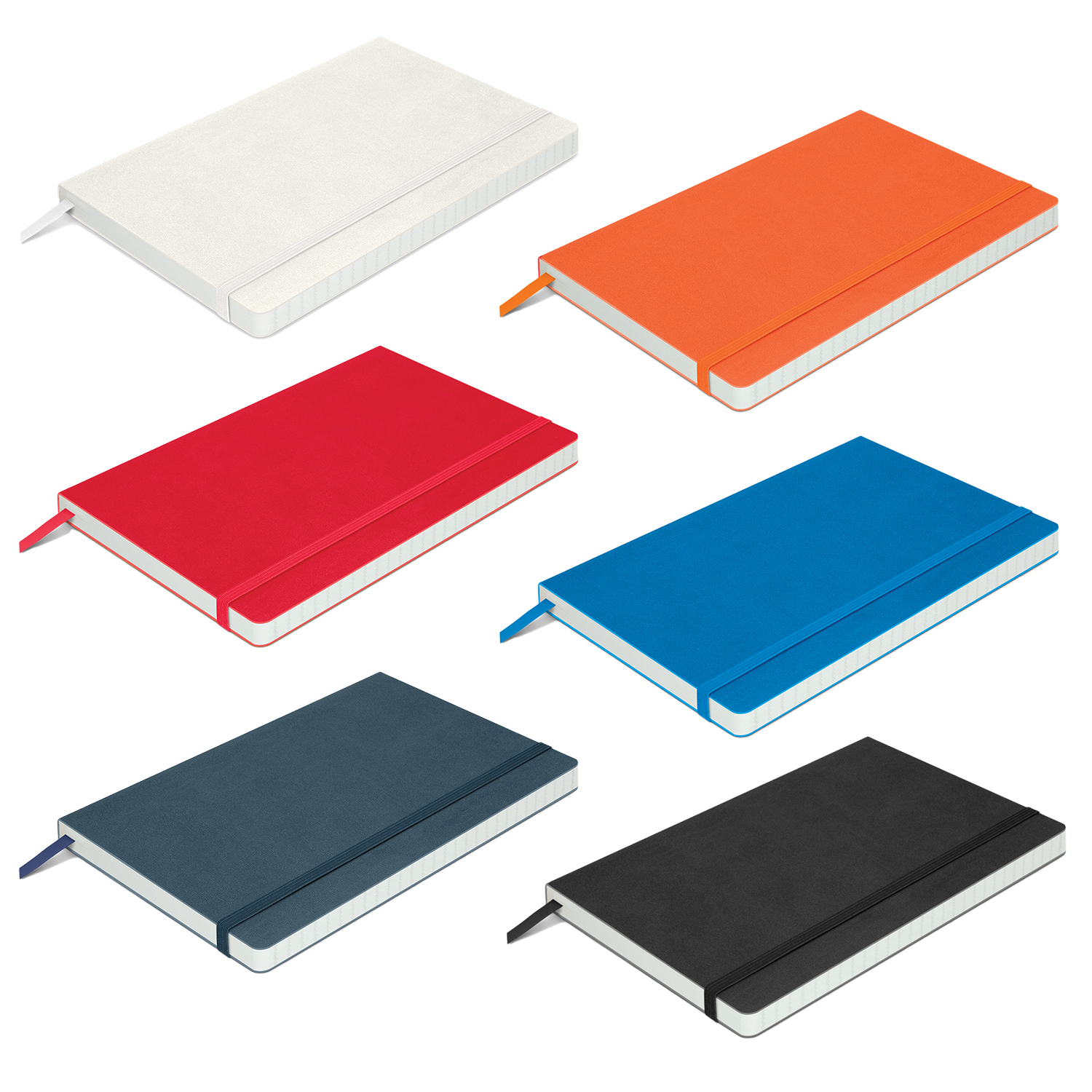

Affordable medium-size (approximately A5) notebook with a soft PU cover which thermo debosses to a stunning two-tone finish. It has 80 leaves (160 pages) of 70gsm lined paper, a bookmark ribbon and an elastic closure band.

Cover Type: Soft

Bookmark Ribbon: Yes

Size: Medium

Page Colour: White

Page Edges: Rounded

Binding Method: Case

Leaves: 80

Page Weight: 70gsm

Approx. Cover Thickness: 1mm

Page Design: Lined

Closure Method: Elastic Band

Country Of Origin: China

Loose packed.

Dimensions:

W 130mm x L 205mm x 10mm.

Additional information

| Decoration | 1 Colour 1 Location Pad Print, 1 Colour 2 Location Pad Print, 2 Colour 1 Location Pad Print, 2 Colour 2 Location Pad Print, 3 Colour 1 Location Pad Print, 3 Colour 2 Location Pad Print, Foil Printing, Screen Print, Thermo Debossing, Thermo Debossing XL |

|---|---|

| Colour | Orange, Red, Royal Blue, Navy, White, Black |

| Material | Offset Paper, Polyurethane (PU) |

| Production Time | 2 Weeks Production Time |

Our guarantee

All of our products are fully guaranteed to work, look and feel as designed.

Our most highly regarded company value at Good Things is integrity. We do what we say we are going to do in a timely fashion. We get "Back in a Flash" to all our clients for quotes, artwork and samples.

It is essential in our industry - from meeting delivery deadlines, through to having a product match a sample when delivered to each minute detail.

When dealing with us you can expect to get exactly what you ordered: as agreed, and on time. That is the Good Things Guarantee.

Product reviews

Hudson Notebook

Min Qty: 50

99.4% jobs

delivered on-time

Free graphic

design

Quotes within

24 hours

Get an instant quote

Description

Affordable medium-size (approximately A5) notebook with a soft PU cover which thermo debosses to a stunning two-tone finish. It has 80 leaves (160 pages) of 70gsm lined paper, a bookmark ribbon and an elastic closure band.

Cover Type: Soft

Bookmark Ribbon: Yes

Size: Medium

Page Colour: White

Page Edges: Rounded

Binding Method: Case

Leaves: 80

Page Weight: 70gsm

Approx. Cover Thickness: 1mm

Page Design: Lined

Closure Method: Elastic Band

Country Of Origin: China

Loose packed.

Dimensions:

W 130mm x L 205mm x 10mm.

Additional information

| Decoration | 1 Colour 1 Location Pad Print, 1 Colour 2 Location Pad Print, 2 Colour 1 Location Pad Print, 2 Colour 2 Location Pad Print, 3 Colour 1 Location Pad Print, 3 Colour 2 Location Pad Print, Foil Printing, Screen Print, Thermo Debossing, Thermo Debossing XL |

|---|---|

| Colour | Orange, Red, Royal Blue, Navy, White, Black |

| Material | Offset Paper, Polyurethane (PU) |

| Production Time | 2 Weeks Production Time |

Our guarantee

All of our products are fully guaranteed to work, look and feel as designed.

Our most highly regarded company value at Good Things is integrity. We do what we say we are going to do in a timely fashion. We get "Back in a Flash" to all our clients for quotes, artwork and samples.

It is essential in our industry - from meeting delivery deadlines, through to having a product match a sample when delivered to each minute detail.

When dealing with us you can expect to get exactly what you ordered: as agreed, and on time. That is the Good Things Guarantee.

Australian-Owned

Australian-Owned

Free Shipping

Free Shipping